Facebook group uses 3D printers to make face shields

Published 7:30 am Friday, April 17, 2020

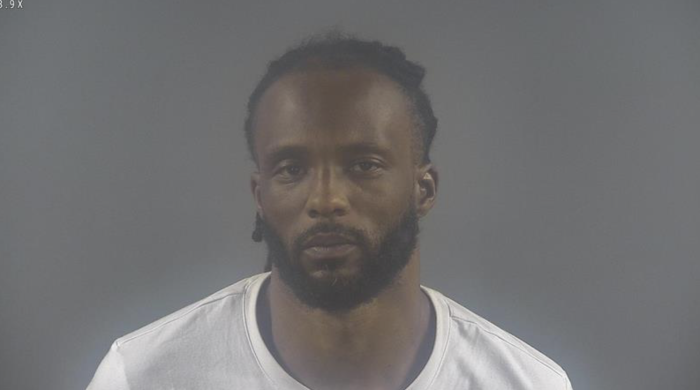

- Adam Almon of Consolidated Electrical Distributors poses for a photo outside his home on Tuesday, April 14, 2020, with the face shields he and eight others in Bowling Green have crafted with 3D printers for use by those battling the coronavirus pandemic. After a delivery to Med Center Health on Tuesday, April 14, 2020, the group has donated 1,040 3D-printed face shields and other tools to the Med Center. (Grace Ramey/photo@bgdailynews.com)

Adam Almon and Chris Harmon are hobbyists, but don’t call their hobby a trivial pursuit.

It may be saving lives.

The two Bowling Green residents have both invested in 3D printers, using them to make toys, Christmas ornaments and other knickknacks.

That is, until the outbreak of the COVID-19 respiratory disease became a worldwide pandemic and they found another use for their devices that build three-dimensional objects from a computer-aided design model.

As the COVID-19 pandemic intensified and health care professionals found themselves in desperate need of personal protective equipment like masks and face shields, Almon went looking for a way to help and chanced upon a Facebook group called #TeamKentuckyMakers.

That statewide social media group has brought more than 100 members on board, and the Bowling Green contingent headed by Almon and Harmon is volunteering to produce face shield frames for health care professionals in southcentral Kentucky.

Almon, who works for Bowling Green’s Consolidated Electrical Distributors, found an open-source visor frame design created by Swedish designer Erik Cederberg and began making them on the two 3D printers he had at his home.

“I sent a couple of face shields (created by attaching overhead transparency sheets to the frame) to The Medical Center,” Almon said. “They requested 5,000 face shields. It blew up more than I thought it would.”

Almon has since invested in a third printer and has enlisted the help of Harmon and others who are now part of perhaps the busiest #TeamKentuckyMakers group in the state.

“The Bowling Green group is putting out more than all of us combined,” said Glen Jones of Mount Sterling, who started the statewide Facebook group. “I basically started the group as a way to make some PPE and get it to where it needs to go. I knew people would jump on board.”

Harmon, a Western Kentucky University employee who has been working from home since the statewide social distancing mandates were put in place, was happy to join the group.

“I was not wanting to feel helpless,” Harmon said. “I wanted to accomplish something.”

He first tried making the N95 masks preferred by medical professionals because they filter out 95 percent of airborne particles.

“I tried printing those, and they take forever,” Harmon said. “And everybody is trying to buy the medical-grade filtering material.”

He then found the Facebook makers group and discovered that making the face shield frames was a good fit for the inexpensive 3D printer he had.

“There are about a dozen of us printing these face shields now,” Harmon said. “Most of us started with 3D printers that cost less than $200.”

Harmon said he could produce about a dozen face shield frames per day with his printer. He was sending frames to medical professionals in Bowling Green and in such nearby communities as Tompkinsville and Scottsville. He even got his three teenage sons involved.

Oldest son Peyton Harmon, a sophomore at South Warren High School, said the frame printing is a good fit for his goals as a Boy Scout.

“Scouts are helpful,” Peyton said. “This is a way to do a good turn daily. I’m just doing it to help, and it counts toward my service hours. I’m glad we’re able to help the community.”

With the help of his sons and the others in the local makers group, Harmon said the group has ramped up production. Almon, in fact, said he was delivering about 700 face shield frames to Med Center Health this week.

Those frames are meeting an urgent need, said Fred Genter, vice president of supply chain for Medical Center parent Commonwealth Health Corp.

“They have been a great help to us, along with others in the community,” Genter said. “We’re in good shape now, but we always welcome donations.”

Almon said the donations from the local makers group will keep flowing until the goal of 5,000 frames has been met, but he doesn’t plan to stop there.

“Once we’re done with that, we’re going to send some to Greenview,” he said. “We’ve already sent some to Evansville.”

Almon has started a Facebook fundraiser that has raised $500 to help cover the group’s expenses, and he said the #TeamKentuckyMakers Facebook page has an intake form that health care professionals can use to place orders for the frames.

“I’m excited about how it has taken off,” Almon said. “We have a good group of people working free of charge. We were all strangers a week or so ago. Now we have a unique opportunity to do something that’s making a difference.”