Clear as glass

Published 12:00 am Tuesday, August 21, 2007

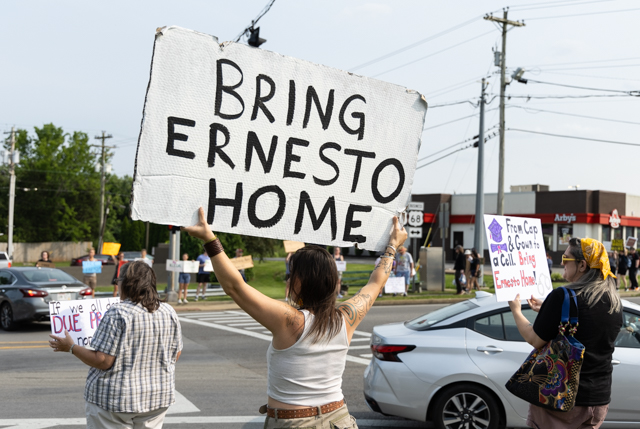

- Photo by Hunter WilsonAnthony Stigall of Bowling Green, a glazer for Kentucky Mirror Plate and Glass, installs insulation Monday around windows at a new building just off Russellville Road.

As the retail glass industry diversifies, local companies say technological innovations, a relatively stable housing market and higher energy prices contribute to the growing trade.

“When I first started, if you were a glazer, you had to know how to do everything,” said Kentucky Mirror Plate and Glass manager Robbie Thompson, meaning from the manufacturing end to the retail end of the spectrum.

Thompson comes to Bowling Green from Lexington, which he said was a very competitive environment for the glass industry.

Thompson has been with the company for 17 years and said he can already tell that Bowling Green’s builders are more laid back and welcoming after moving to Bowling Green last month.

Today, there are more companies that specialize in various parts of the glass production and sales process, he said.

“Since the unions went away, the glass companies have begun to diversify,” Thompson said.

Around 1987, unions faded out in Louisville for glass companies, according to Thompson, because of the price of insurance and other factors.

But such unions can still be found in Nashville, Indianapolis, Kansas City, Mo., and other metropolitan areas.

Kentucky Mirror Plate and Glass offers glass creations ranging from residential and commercial items, to custom tabletops, shower stalls and sandblasted designs.

The 50-year old Louisville-based company opened its Bowling Green office in 2005 and recently debuted a new staff, Thompson said. The owners of the company are Alec and Carole Spielberg.

The local Kentucky Mirror Plate and Glass has been responsible for the glass touches behind some of the city’s recent well-known projects, including a new front for Pearce Ford Tower, the tallest residence hall in the state at Western Kentucky University, the new Nation’s Medicines building on Fairview Avenue, and the new Bowling Green Area Chamber of Commerce building on College Street.

Many builders are also beginning to use glass companies as a one-stop shop, Thompson mentioned.

“They want everything from one vendor,” he said. “Builders just want something easier.”

The cost of offering more sophisticated designs has also decreased as robotic beveling machines provide polished products at a fraction of previous costs, according to Thompson.

But higher energy prices are more than making up the difference – the price of aluminum has shot up at least 50 percent, according to other window companies in the area.

“The growth is happening in our industry because everybody is wanting to have the lower heating and cooling bill,” Window City owner Sandra “Sam” Graham said.

Graham said people are more willing to take advantage of getting the $200 tax credit available until the end of the year for energy efficient windows, since at least 80 percent of the heat in a house is lost due to a lack of insulation in windows and doors.

Window City opened its doors in Hadley in January.

For Bowling Green Glass Co., which mainly handles residential replacement windows and glass needs for new commercial construction, most of the growth in the glass industry is a residual effect from growth in the local economy as a whole.

“The growth that we’ve seen in the last three or four years is really the economy in general,” said Bowling Green Glass Co. owner Jim French. “There’s building going on everywhere – they all need windows and doors.”

French said the other thing that contributes to an increase in sales for his company is, unfortunately, rising energy costs.

“As energy costs go up, my material costs go up, which contributes to a higher monetary sale,” French said. “Our base price really hasn’t gone up.”

But French said the energy surcharge he faces has fluctuated between 5 percent to 10 percent over the years.

– To see what type of windows are recommended for the southcentral Kentucky area, go to http://www.efficientwindows.org.

Glass industry facts

€The glass industry is an integral part of the American economy and everyday life.

Many consumer products, ranging from food and beverage packaging, lighting products for homes and businesses, automobile windshields, and windows in buildings to insulation for buildings, fiber optics for communications, and tubes for televisions, all involve glass.

€The U.S. glass industry is a $28 billion enterprise with both large producers and small firms playing pivotal roles in the industry. While most sectors of the glass industry have restructured and consolidated in the past 20 years, the industry still employs more than 143,000 workers who earn an average of $16.14 an hour.

€On a percent-of-shipments basis, glassmaking is one of the most energy-intensive industries – the industry spent $1.8 billion on purchased energy in 2001.

Source: U.S. Energy Information Association